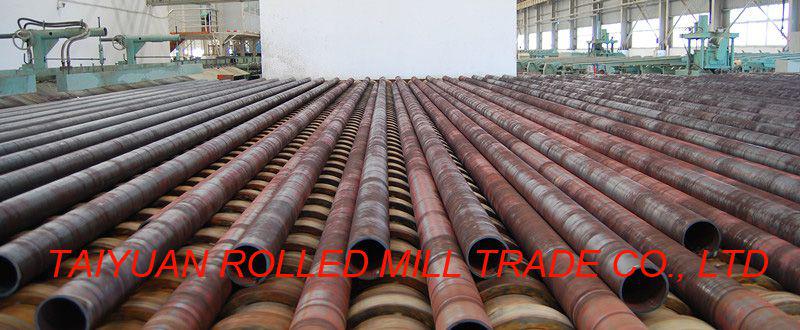

Introduction for Φ141.3 hot rolling mill production line for ERW tube

Summarize

Hot rolled ERW pipe means (ERW pipe change to seamless )that heat ERW pipe as mother pipe with HF electric resistance welded to roll in tension reducing mill (SRB) to make ERW pipe welded seam metallurgical structure same as mother pipe basic structure completely and get final finished pipe sized and wall thickness, the characteristic as:

lThe pipe which in hot rolled with characteristic that both ERW steel is in high purity and its structure are high density, good toughness, high precision, especially equal wall thickness etc.

lTo compare with seamless pipe (SML), the rate of finished ERW pipe length will be up and length will be longer than 40 m、80m after tension reducing mill in hot rolling.

lThe heat affecting area and unsteadily factors will be exterminated while welded steel pipe and make steel mother pipe and welded seam microstructure be uniformization.

lWith this method of production, it can up steel pipe production output to compare with same sized SML seamless pipe production line.

lWith SRB rolling process, it can be produced widely in size of diameter 21.3~141.3mm from ERW pipe mill only need 1 or 2 sized mother pipe to compare with ERW pipe mill line in full size range, and it increased production efficiency and simplified ERW pipe mill process and its tooling.

Products performance standard

ASTM A 53/A 53M-05 Pipe, steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

ASME B36.10M-2004Welded and Seamless Wrought Steel Pipe

API 5L Specification for Line Pipe

API 5CT Specification for Casing and Tubing

Production process:

Quality steel strip--Φ168 HF welded pipe mill-- Fast heat furnace-- Heat billet pipe to Max. 1000℃--24 Stands tension reducing mill-- Rotary flying hot saw machine --Unstressing roll cooling bed (On line straighten)-- Facing/ Chamfering pipe ends-- ETC /Ultrasonic detecting-- Inspection by visual -- Packing to store

Main equipment description

Tension reducing mill

Used to roll finish steel pipe in series sizes from ERW pipe heated. After heating furnace

Main parameter of mother pipe

Before rolling pipe size:φ168×10.92

Before rolling pipe length:Max25000 mm

Dia. departure of mother pipe at entrance: (+1%~-1%)D

Temperature of mother pipe at entrance: ≥950 ℃

Equal temperature of pipe in length way : ±15℃

Finish pipe

Finish pipe diameter:21.3~141.3 mm

Pipe length after rolled: Max 84000 mm

Rolling mill

Mill stand Number:24 sets and 24 sets of motor

At entrance rolling speed:0.5~0.75 m/s

At exit rolling speed:max 3.33 m/s

Total reduction rate mill line: max 78%

Single stand roller numbers: 3 Pieces

Equip with hydraulic system and oil lubrication system

Structure

This mill line is consist of 24 sets of motors, a set joint reducer, main mill base seat, rollers replacement device, roller stands, guide roll stands, pipe guide stand, intermediate couplings, lifting apparatus electric driving system, basic automation control system, operating consoles, hydraulic and lubrication system etc.

Rotary type hot flying saw machine

To cut off pipe head, tails and length fixed, After roll conveyer of tension reducing mill.

Technical parameter

Pipe Dia. To cut off:Φ21.3~141.3 mm

Wall thickness:≤12.0 mm

Temperature at cutting: Min 700 ℃

Cutting action speed:0.5~4.5 m/s

Cut to length: 4.5-12.5m , at high speed, minimum length: 4.5 m;

Steel pipe running speed:0.6--6.0m/s

Precision to cut off:±10mm

Length tolerance to cut: ± 30 mm

Incline allowance of cut pipes: ± 1°

Structure

Rotary hot flying saw machine is cutting pipe in high precision to length. Composed saw machine bodies, saw blade on arm of motor, guide wheel, main motor, reducer, measuring device etc. machine external of saw blade equip with protection safety cover.

The pipes sized cut off after hot flying saw machine, will be transported to roll type cooling bed through roll conveyer.

Unstressing roll cooling bed

Be cooling pipes after roll conveyer of flying saw machine.

Technical parameter

Diameter:Φ21.3~141.3 mm

Length: Max 12000 mm

Roll barrel length:14000 mm

Roller numbers:60 Pieces

Cooling bed length: ~18000 mm

Roller rotary speed:~5 r/min

Structure

The cooling bed divided into 5 groups of roller sets, each group consist of motors, reducers, chain system driving 12 pieces of hollow roller, and rollers are cooled with water inside, and equip with back-up roller under each roller.

The roller are rotated to exit direction, the pipes are rotated its self in counter rotation with friction of steel pipe and go forward.

晋公网安备 14010702070482号

晋公网安备 14010702070482号