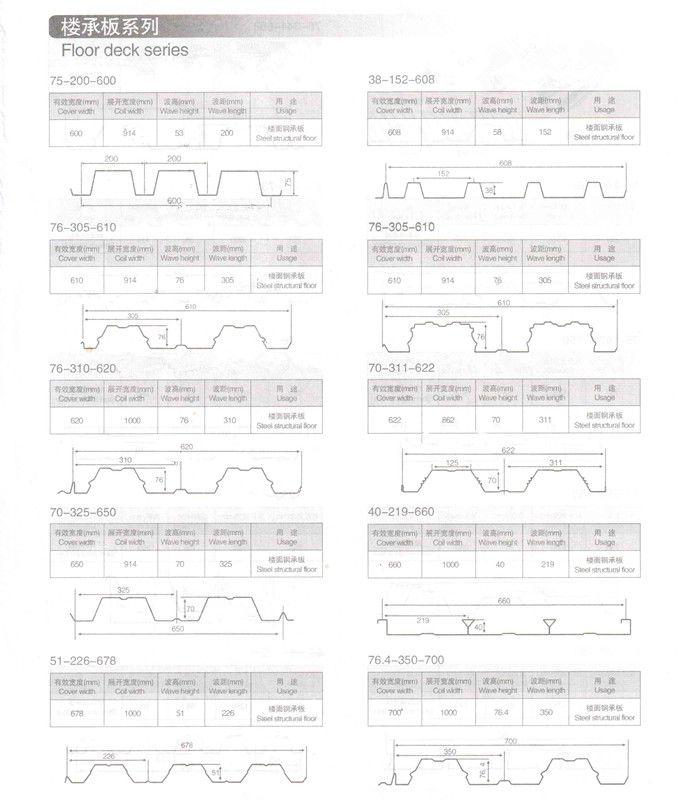

475 Floor decks profiling equipment

The profiles rolled on model 475 floor deck roll forming machine are widely used in high building structure with the features of light weight, high strength, heavy load bearing, good earthquake resistance etc.

475 Floor deck forming mill

1) Auto-de-coiler

a. Coil inner diameter given by buyer

b. Coil width:1000mm

c. Coil weight Max.:6000kg

d. Hydraulic station motor power:3kw

e. Hydraulic motor power:3kw

f. Cylinder inner diameter:120mm

g. Working pressure:10Mpa

2) Main forming mill

a. Stands numbers: 24

b. Main shaft steel brand: 1045, diameter: 80mm, roller steel brand: 15GCr, hardness: HRC58-60°;

d. Main mill motor power:22kw

e. Rolling speed:9-12m/min

f. Frame structure: 350 I beam welded.

g. Roller surface hard chrome thickness: 0.05mm.

3) Hydraulic cutter: Cr12

a. Cutting die harden heat treatment

b. Hydraulic cutting system: Auto-cutting after forming mill stopping, Non deform, Non waste tip, high safety coefficient.

4) Electric control system

a. Screen touching to control: 5.7” Taida brand touch screen;

b. Main electric control system: DVP14ES PLC Taida, Taiwan.

c. Encoder: AUTONIC ENC-1-1-1t-24 Korea

5) Hydraulic system: Taiwan, 4kw

The floor decks are used in general power station, mobile exhibition hall, steel structure workshop, cement house, steel structure office, airport waiting room, train station, stadiums, music hall, Grand theatre, super market, logistics center etc.

To meet fast construction working requirements and fabricate a stronger working platform in short time, it can use as many floors in multiple layers, also it cast in concrete board use.

------------------------

688 mode machine composed: manual type de-coiler, forming mill, hydraulic system and die cutting machine, electric control system, run out table.

Thickness of floor deck: 0.8mm、1.0mm、1.2mm; width: 688mm~940mm,High:5 1 mm ~76mm;

Main specification of 688 machine:

1、Installation dimension: L15×W1.5×H1.2

2、Roll forming stands numbers: 26

3、Roller material: 45# steel

4、Roller Chromium plating coating: 0.05mm

5、Die material: Cr12

6、Roll forming speed: 9-10m/min.

7、Electric control system: By PLC control

8、Main motor power: 11KW* 2 Sets

9、Hydraulic station power: 4KW

10、Strip thickness: 0.8-1.2mm

11、Strip open width: 1000mm

Main specification of 720 machine:

1、Installation dimension: L15×W1.5×H1.2

2、Roll forming stands numbers: 26

3、Roller material: 45# steel

4、Roller Chromium plating coating: 0.05mm

5、Die material: Cr12

6、Roll forming speed: 9-10m/min.

7、Electric control system: By PLC control

8、Main motor power: 11KW* 2 Sets

9、Hydraulic station power: 4KW

10、Strip thickness: 0.8-1.2mm

11、Strip open width: 1000mm

晋公网安备 14010702070482号

晋公网安备 14010702070482号